- 0

- 0

- 0

- 0

- 0

On September 6, 2025, the Sixth Tongji Forum on the Development and Innovation of Bridge Engineering Technology and the First Forum on the Development and Innovation of Prestressed Technology were successfully held in the Yifu Building Auditorium of Tongji University, with a simultaneous online meeting.

On September 6, 2025, the Sixth Tongji Forum on the Development and Innovation of Bridge Engineering Technology and the First Forum on the Development and Innovation of Prestressed Technology were successfully held in the Yifu Building Auditorium of Tongji University, with a simultaneous online meeting. Prestress Technology has added Prof. Luc Taerwe from Ghent University, Belgium as Co-Editor-in-ChiefOn November 13, 2024, it was decided at the meeting of the editors-in-chief of Prestress Technology that Prof. Luc Taerwe would be added as Co-Editor-in-Chief of the journal, injecting a new force into the international development of the journal. Previously, Prof. Luc Taerwe was a member of the Editorial Board of Prestress Technology.

Prestress Technology has added Prof. Luc Taerwe from Ghent University, Belgium as Co-Editor-in-ChiefOn November 13, 2024, it was decided at the meeting of the editors-in-chief of Prestress Technology that Prof. Luc Taerwe would be added as Co-Editor-in-Chief of the journal, injecting a new force into the international development of the journal. Previously, Prof. Luc Taerwe was a member of the Editorial Board of Prestress Technology.

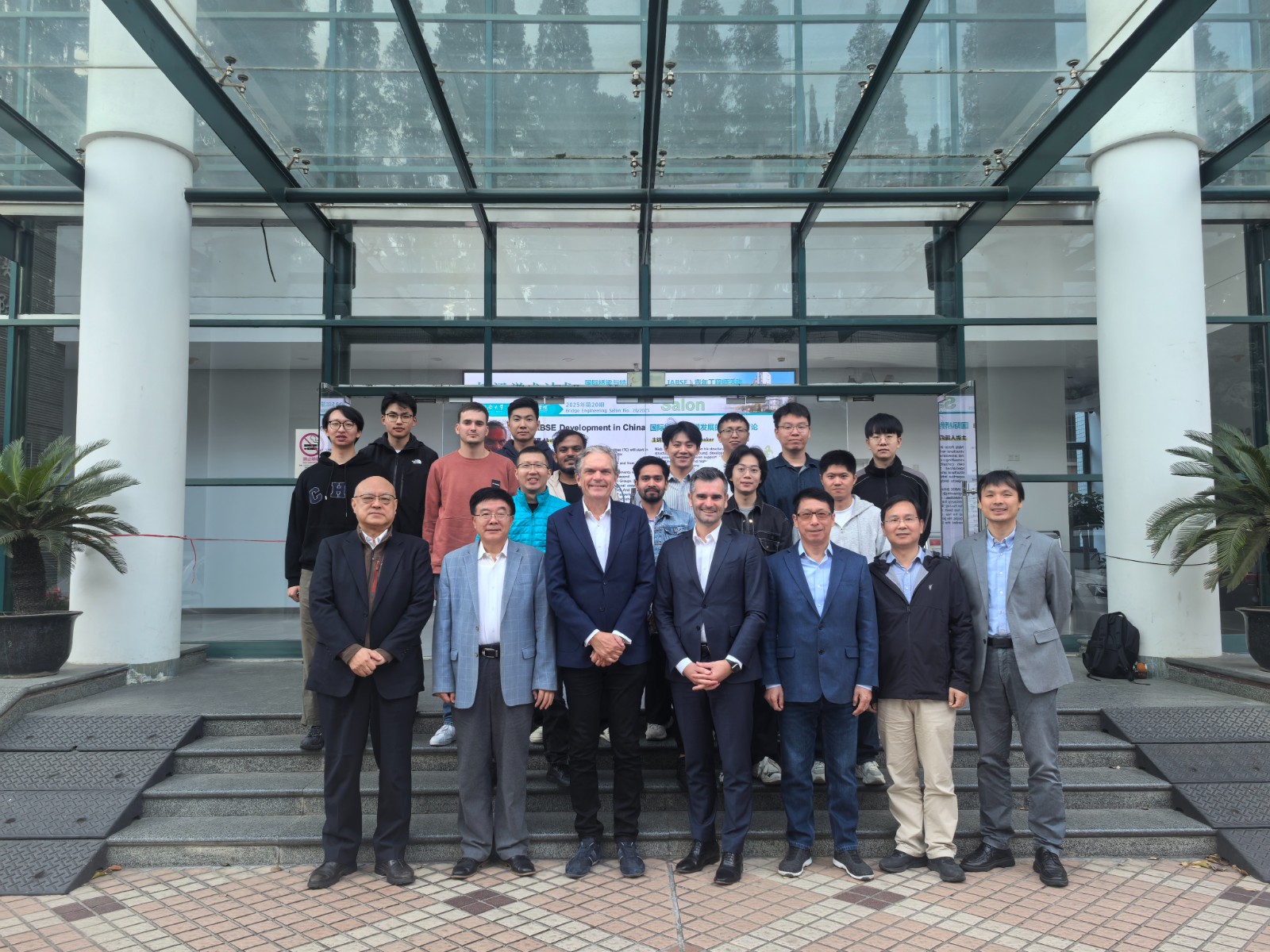

Mr. Niels Peter Hoj, Chairman of the International Association for Bridge and Structural Engineering Technical Committee (IABSE TC), visited Tongji University on October 22, 2025, and engaged in a journal exchange.

Mr. Niels Peter Hoj, Chairman of the International Association for Bridge and Structural Engineering Technical Committee (IABSE TC), visited Tongji University on October 22, 2025, and engaged in a journal exchange. Prestress Technology : An International Journal (PT) is an Open-Access, peer-reviewed journal that publishes articles which contribute new results in prestressing fields of the Civil Engineering,Nuclear Engineering, Energy Engineering. The journal is devoted to the publication of high quality papers on theoretical and practical aspects of Prestress technology. The goal of this journal is to bring together researchers and practitioners from academia and industry to focus on prestress technology advancements, and establishing new collaborations in these areas. Original research papers, state-of-the-art reviews are invited for publication in all fields of prestress technology.

Prestress Technology : An International Journal (PT) is an Open-Access, peer-reviewed journal that publishes articles which contribute new results in prestressing fields of the Civil Engineering,Nuclear Engineering, Energy Engineering. The journal is devoted to the publication of high quality papers on theoretical and practical aspects of Prestress technology. The goal of this journal is to bring together researchers and practitioners from academia and industry to focus on prestress technology advancements, and establishing new collaborations in these areas. Original research papers, state-of-the-art reviews are invited for publication in all fields of prestress technology.

- Current Issue |

- Online First |

- Special Articles |

- Discussion Corner |

- Archive

-

2025,3(04):1-10 ,DOI: 10.59238/j.pt.2025.04.001

Abstract:With increasing societal awareness of environmental protection, the production process of traditional cement has become an area in urgent need of innovation because of its significant carbon emission contributions and generation of industrial solid waste. As a new type of low-carbon cementitious material, geopolymers not only consume less energy and produce fewer carbon emissions but also effectively allow for the reutilization of industrial solid waste, demonstrating its immense potential for further development. However, the inherent brittleness and poor crack resistance of geopolymers limit their structural applications. The crack resistance of concrete can be significantly improved by utilizing self-stressing structures to generate internal stress or by taking prestressed concrete with its unique manufacturing methods. Furthermore, incorporating admixtures to enhance the material's inherent crack resistance presents another viable strategy. Owing to their excellent mechanical properties, carbon nanotube fibers offer new possibilities for addressing these limitations of geopolymers. In this review, the use of carbon nanotubes (CNTs) to enhance geopolymer performance is investigated. A comprehensive analysis of existing studies reveals that the incorporation of CNTs significantly improves the crack resistance and mitigates the brittleness of geopolymers. Optimal overall performance is frequently reported at CNT dosages between 0.12 wt.% and 0.14 wt.%. These findings provide a theoretical foundation for the practical engineering of CNT-reinforced geopolymers and contribute to the development of sustainable construction materials.

-

Chunxu Yang, Fan Yang, Haining Zuo, Yiqing Zou

2025,3(04):11-24 ,DOI: 10.59238/j.pt.2025.04.002

Abstract:A welded bearing plate is a novel structural component for force transmission in prestressed concrete. Its bearing capacity in the anchorage zone is directly related to the overall safety of the prestressed concrete structure. Elastoplastic deformation, damage evolution, and failure mechanisms within the anchorage zone under prestressing loads remain pivotal scientific issues that necessitate in-depth investigation. In this study, a numerical model of the concrete anchorage zone with welded bearing plates is developed with ANSYS software. Comprehensive simulations are carried out to analyze the structural response from initial deformation to ultimate failure under cyclic and vertical displacement loads. The accuracy of the proposed numerical model is verified through a comparative analysis with existing experimental results. Parametric studies are conducted to systematically assess the influence of key design parameters, such as the base plate thickness, flared tube diameter, and wall thickness, on the stress distribution and ultimate load, leading to structural optimization of the bearing plate, which is further validated by physical testing. The results indicate that the plastic-damage microplane model effectively captures the localized compressive behavior and agrees with the experimental observations, thus confirming its feasibility and applicability. In addition, the load-carrying capacity and stress distribution are significantly improved by increasing the base plate and flared tube thickness, with the base plate thickness having a more pronounced effect. Both parameters are generally positively correlated with structural performance. In contrast, variations in the flared tube diameter have a relatively marginal effect. Following structural optimization, the load-transfer performance of the welded bearing plate is superior to that of the original design, particularly in terms of its higher ultimate load capacity and ability to controls cracks control (i.e., delayed initiation and reduced propagation). These findings provide valuable theoretical insights and data support for evaluating load capacity, understanding stress distribution mechanisms, and optimizing the engineering design of concrete anchorage zones.

-

Yuhao Li, Haiying Ma, Sao Chivorn, Bin Yan, Qiang Liu, Komarizadehasl Seyedmilad

2025,3(04):25-39 ,DOI: 10.59238/j.pt.2025.04.003

Abstract:Curved-girder bridge systems, owing to the bending–torsion coupling effect, tend to rotate out of plane under vertical loading. Compared with straight girder bridges, curved-girder bridges face greater difficulties during construction, particularly in regard to cross-frame installation. Three types of cross-frame detailing methods are employed, where the cross-section achieves the desired fit on the basis of the load type: no load fit (NLF), steel dead load fit (SDLF), and total dead load fit (TDLF). One of these methods determines the bridge’s final shape and workability; thus, in this study, curved multiple-girder bridges with different curvatures are studied numerically to examine the effects of different cross-frame detailing methods on the internal forces, deformations, and load-bearing capacities of curved-girder bridges. This study focuses on the construction stage, so only the steel dead load and weight of the concrete slab are considered. The analysis results reveal that for bridges with small curvature radii, the use of an SDLF or a TDLF reduces bridge deformation (vertical deflection and rotation) but increases internal forces relative to the NLF. When the curvature radius increases, the influence of the SDLF and TDLF on the bridge’s response diminishes. The study findings can be helpful for choosing proper detailing methods to use in the construction of composite curved I-girder bridges with various curvature radii.

-

2025,3(04):40-51 ,DOI: 10.59238/j.pt.2025.04.004

Abstract:While the theories and methods for designing the steel sections of wind turbine towers are relatively well established, the design of concrete tower sections, particularly the methodologies for concrete fatigue design, varies across different codes and standards. These methodologies often involve complex calculation parameters and formulas, which can be prone to misinterpretation and misapplication. This paper primarily traces the evolution of provisions in the fib Model Code and the Eurocode, offering recommendations for determining concrete mechanical properties, structural analysis methods, and fatigue design approaches. Furthermore, a concrete fatigue calculation example is presented based on an engineering case study. This example illustrates key considerations for selecting critical parameters and applying the relevant calculation formulas. The aim is to provide a more in-depth understanding and improve the application of concrete fatigue design principles.

-

Zuen Xu, Qi Su, Lingfeng Zhu, Yaolin Wei

2025,3(04):52-63 ,DOI: 10.59238/j.pt.2025.04.005

Abstract:China has entered a period of large-scale bridge maintenance, and long-span cable-stayed bridges in service for more than 15 years are frequently facing issues such as water seepage at anchorages, excessive humidity, and corrosion of steel components. Via traditional sealing and monitoring methods, it is difficult to detect hidden hazards in concealed areas in a timely manner. In this paper, an anchorage end protection system that integrates visual monitoring and active humidity control while accounting for sealing conditions is proposed. Using actual cases such as the Jintang Bridge and Taoyaomen Bridge from the Zhoushan Island Link Project, the shortcomings of traditional maintenance measures and the causes of defects are analyzed. Experimental and onsite validation demonstrate that this system effectively delays corrosion, enhances detectability, and improves maintenance efficiency, providing an engineering reference for the full-lifecycle management of large-span cable-stayed bridges.

-

2025,3(04):64-73 ,DOI: 10.59238/j.pt.2025.04.006

Abstract:Nanhai Avenue, located in Nanchong, Sichuan, is a major urban road built along mountains. The project involves the comprehensive treatment of a high and steep slope, which is characterized by elevated height, complex geological conditions, and a large volume of landslide mass. Moreover, the newly constructed bridge structure that is present adjacent to the slope poses strict requirements for slope deformation control. Based on the high-slope project on Nanhai Avenue in Nanchong, in this paper, a finite element model is constructed using Plaxis software to study support measures for high slopes. The results reveal that in slope protection, anti-slide piles play a crucial role in bearing the majority of the landslide force, and after prestress is applied, frame anchor cables can significantly share the landslide force, reducing the displacement and internal force of anti-slide pile shafts. Frame anchor cables transfer the landslide force to deep anchored soil layers, significantly reducing the deformation of soil behind piles, which plays a key role in controlling deformation of the bridge adjacent to the slope and ensuring the safety of the bridge structure. It is anticipated that the results of this study will provide reference data for similar projects in the future.

-

Wei Wang, Huaiyue Shi, Chunsong Gao, Chao Liu

2025,3(04):74-88 ,DOI: 10.59238/j.pt.2025.04.007

Abstract:With the increasing urbanization in China, the scale of urban elevated bridge construction continues to expand. Conventional ground-supported formwork systems face significant challenges in the construction of high-pier, large-span prestressed bent caps. These traditional systems, characterized by large site occupancy and high material consumption, often lead to low construction efficiency. Particularly in space-constrained urban centers, their bulky support structures severely disrupt surrounding traffic and fail to meet urban bridge construction demands. In this paper, a lightweight, ground-free formwork support system for high-pier bent caps is systematically investigated. By employing novel materials and structural forms, such as acrylonitrile-styrene-acrylate (ASA) polymer-reinforced alloy formwork and ground-free steel supports, the system achieves lightweight, modular, and green construction. It innovatively addresses multiple technical difficulties inherent in traditional methods, significantly reduces carbon emissions during construction, improves material reusability, and embodies the concept of sustainable construction. Engineering practices in typical projects, including Wenzhou Wenrui Avenue, Hangzhou Shidai Avenue, and Ningbo Jiulong Avenue, have demonstrated the marked effectiveness of this system. It has significant advantages in terms of construction efficiency, cost control, resource conservation, and environmental impact, indicating substantial potential for broader application.

-

2025,3(04):89-94 ,DOI: 10.59238/j.pt.2025.04.008

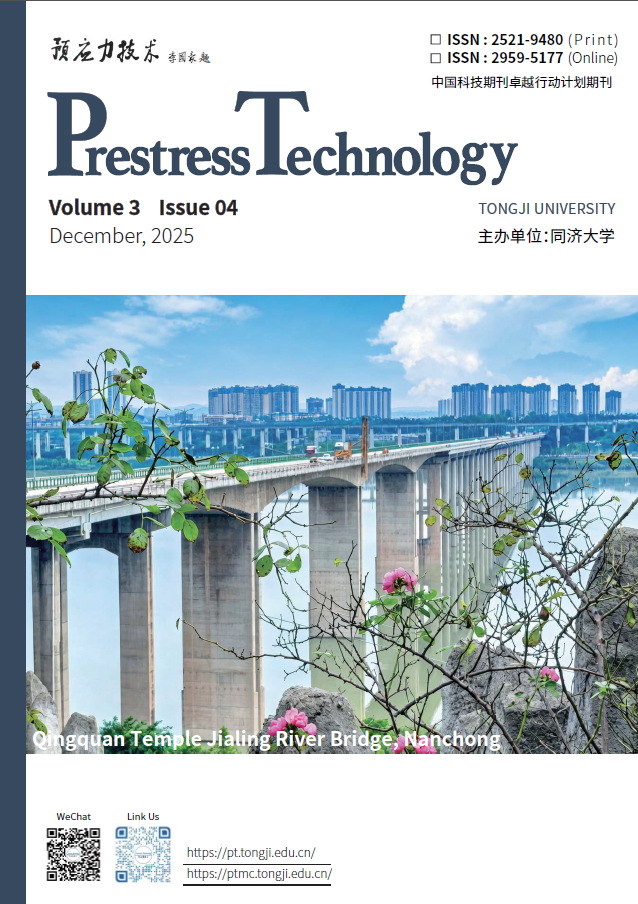

Abstract:To systematically evaluate the long-term performance of external prestressing technology and promote its engineering application, the international journal Prestress Technology of Tongji University recently organized a specialized symposium and conducted onsite follow-up visits and technical exchanges on two representative projects—the Xintan Qijiang Highway Bridge in Chongqing (completed in 2008) and the Qingquan Temple Jialing River Bridge in Nanchong, Sichuan (strengthened in 2014). The investigation revealed that, as China’s first long-span continuous rigid-frame bridge employing a hybrid internal–external prestressing tendon system, the Xintan Qijiang Bridge has maintained good technical conditions in its right span with a hybrid tendon layout after 17 years of service, with no structural load-induced cracks, which fully verifies the long-term reliability and durability of the external prestressing system. Moreover, ten years after the implementation of comprehensive strengthening measures—including internal-box external prestressing—the Qingquan Temple Jialing River Bridge also remained structurally stable. On the basis of these findings, experts have recommended the development of dedicated inspection guidelines for external prestressing systems, with a focus on critical components such as anchorages and deviators, and the promotion of nondestructive testing and intelligent monitoring technologies. This investigation not only provides valuable empirical support for the application of external prestressing technology in both new and reinforced bridges but also emphasizes the importance of integrated collaboration among research, industry, management, and maintenance for the sustainable advancement of the technology.

Volume 3,2025 Issue 04

>Reviews

>Scientific Research

>Product Research and Development

>Design and Construction

>Investigation Report

Executive Editor in chief: Fangyuan Li; Albert de la Fuente

Special Issue

Special Issue Virtual Special Issue

Virtual Special Issue